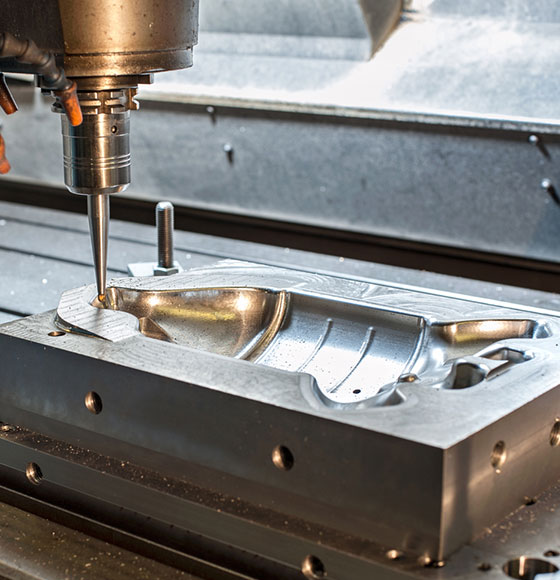

Application companies have always been interested in the problem of extending the life of die-casting molds. This is a topic that has been of concern to them. There is a reasonable selection of materials for die-casting mold forming parts, which is something that has been brought to the attention of the majority of die-casting mold manufacturers and purchasers.

We compared and contrasted the die-casting mold materials that were specified in the standards with the mold steels of the United States of America, West Germany, the United Kingdom, Sweden, and the Soviet Union during the late 1970s when we were in the process of translating the die-casting standards for DCSP1 aluminum alloy and DCSP2 zinc alloy that were developed by the Japan Die Casting Association. These standards were developed by the Japan Die Casting Association. As a consequence of this, we made the decision to carry out experimental research on 4Cr5MoSiV1 steel, and we asked the Fushun Steel Plant to melt it in accordance with the technical conditions that we had developed. These are the most significant points, which are listed below.

To begin, the chemical composition and impurity content should be in accordance with the expectations. This is the most important aspect. Making it mandatory that the ratio of steel forging must be greater than 4S is the third solution that can be implemented. Therefore, it is an essential type of promotion steel that is utilized in the process by which our nation develops national standards for die-casting molds. This process is carried out throughout the United States.

Air-cooled hardening hot-working die steel high pressure die casting part, also known as H13 steel, is a type of steel that possesses both strength and toughness. These are two characteristics that are shared by H13 steel.

1) It has a high resistance to thermal cracking and can be cooled with water in the workplace. Third, it is environmentally friendly.

2) The low carbon content of the material results in a poor secondary hardening ability during the tempering process.

3) Although it is able to withstand the softening that takes place at higher temperatures, the material's hardness reduces at a rapid rate when the temperature at which it is being used is higher than 540 degrees Celsius (1000 degrees Fahrenheit).

4) A moderate level of resistance to the decarburization process).

More specifically, the mass fraction, which is also referred to as the carbon content, is less than zero in H13 steel. It is estimated that approximately five percent of steel is composed of carbon, which, in conjunction with high pressure die casting part other carbide-forming elements, is responsible for the steel's characteristic material properties. Because of its high hardenability and good softening resistance, the steel can be hardened under air cooling conditions, and its maximum quenching hardness is approximately 55 HRC. Because of these characteristics, the steel can be hardened.

An unreasonable structural design was used for the casting, which led to the mold having sections that were extremely thin. When the casting is fractured, these thin sections become the source of the fracture. Consequently, the wall or core of the mold will be eroded as a consequence of this fact.

A significant number of instances of early deformation or fracture come about as a consequence of the one-sided emphasis that is placed on the preservation of steel. The thermal conductivity will decrease, and thermal fatigue will occur earlier than anticipated, in the event that the matching accuracy level of each component is not properly selected, or if gaps are present. Both of these scenarios are possible. There has been some consideration given to the utilization of rapid ejection mechanisms in contemporary mold structures. On the one hand, it is implemented to enhance the efficiency of production; on the other hand, it is also implemented to decrease the amount of time that castings are retained in the mold and to eliminate the thermal load that is placed on the mold material.

It is of the utmost importance that the thermal balance of the mold be taken into full consideration during the design process of the mold. This is necessary in order to guarantee that the mold is able to keep a consistent and reasonable working temperature. This is due to the fact that molten metal is injected into the mold cavity during the die-casting process at some point during the process. The result of this is that a considerable amount of heat is released in a very short amount of time, which in turn causes the temperature of the mold to increase.

Conduction, convection, and radiation are some of the processes that the mold goes through simultaneously. Additionally, the mold surface spraying and cooling water absorption processes are also taking place. A portion of the heat will cause the temperature of the mold to drop, which will be the result of the mold. Over the course of this time period, there will not be a substantial shift in the temperature of the mold. An additional factor nodular cast iron that determines the extent is the mold's ability to maintain a consistent temperature. According to standard practice, this equilibrium temperature is maintained at forty percent of the temperature at which the alloy is poured.

This is because there is a temperature gradient in each component of the mold, and the temperature is constantly changing throughout the cycle. This is the reason why this is the case. Furthermore, because of the disparity in wall thickness of the casting, this temperature is also in a state of constant change. The process of die-casting zinc alloy is not dissimilar to other molding processes in terms of their similarities and differences.

It is important to note that zinc alloy die castings of superior quality are characterized by a number of product characteristics nodular cast iron, including the following:

It has a higher specific gravity, weight, and texture than plastic injection molding, and it is more durable than plastic injection molding. 1. It is more robust than plastic injection molding. It is able to die-cast precision parts that have intricate shapes and thin walls, and the surface of the castings that it produces is smooth. Its excellent casting performance can be attributed to each and every one of these characteristics. During the melting and die-casting processes, it does not attract iron, it does not prevent the mold from corroding, and it does not adhere to the mold by binding to it.

Comments (0)